Industry 4.0 is in the midst of a digital transformation accelerated exponentially by rapidly growing technologies such as sensor technology, robotics, drones, 3D printing, the Internet of Things (IoT), Big Data, and augmented reality. This industrial revolution is destined to revolutionize the manufacturing and production industry thanks to the Internet of Things, cloud computing, data integration, and technological advances in production management software.

These trends do not just mean an increase in production automation, but a disruptive approach to the way we produce and understand the entire value chain. Industry 4.0, therefore, is a concept that unites the technologies that gave way to the third industrial revolution, automation processes, and new production technologies, with the technologies of the information age such as the storage, processing, and massive transmission of data. The most important characteristics that distinguish Industry 4.0 from traditional industrial production are absolute integration and real-time interactivity of all production processes, ensured using modern digital technologies

Design principles

The design principles that organizations rely on to implement Industry 4.0 are as follows:

– Decentralized Decisions. Cyber-Physical Systems have to be able to make decisions on their own and perform their tasks as autonomously as possible.

– Interoperability. People, devices, sensors, and machines must be able to communicate with each other, allowing a machine to identify problems and solve them independently. This has given rise to the IIoT (Industrial Internet of Things), a concept that refers to the connection between data, machines, and people in manufacturing.

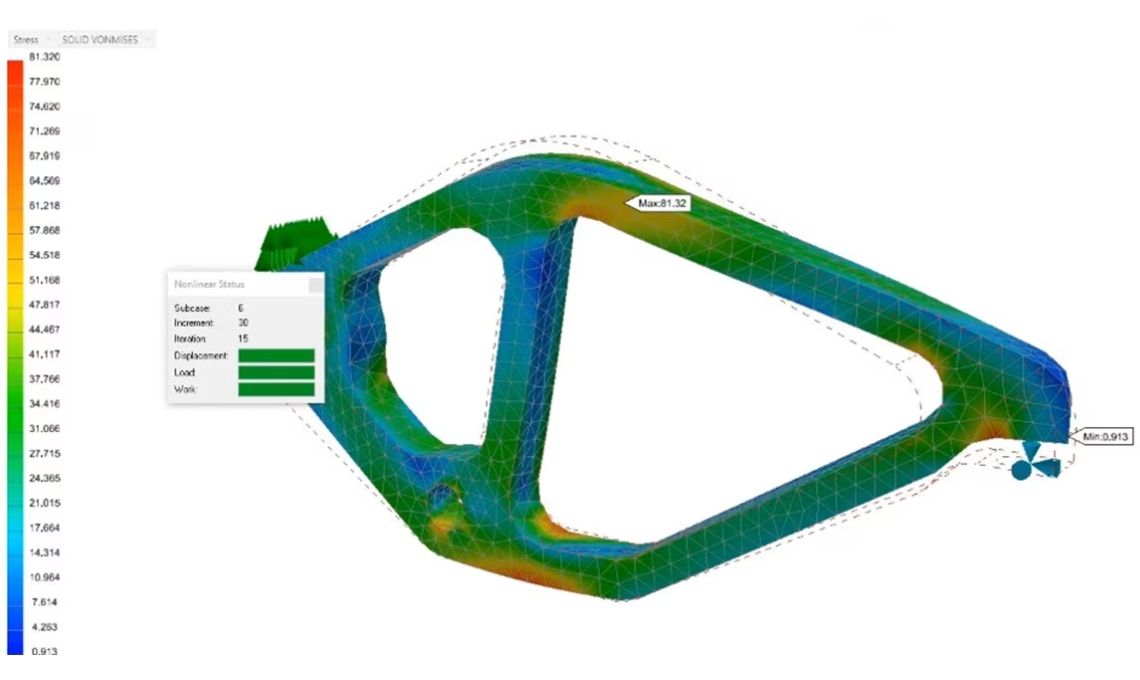

– Technical assistance. Cyber-physical systems have to offer humans support and collaboration in all those dangerous, tiring, or unpleasant tasks. In addition, they must provide intelligible visual information that allows companies to identify potential problems and solve them in the shortest possible time.

-Information transparency. Information systems have to be able to create a virtual copy of the physical world around them with the data collected by its sensors and other connected devices within the ecosystem.

The challenges of Industry 4.0

As Industry 4.0 evolves, the manufacturing industry business model is changing and new models are emerging. Therefore, companies already positioned in the market must act fast to recognize and react to these new competitive challenges.

The development of software and analytics systems that turn the deluge of data produced by smart factories into useful and valuable information. Organizations must generate networks to integrate all players in the value chain. Industry transformation will occur not only vertically, but also horizontally. These horizontal integrations will create flexible and highly responsive networks.

The extensive network of connections and the large amount of data involved in Industry 4.0 will dramatically increase the need for cyber security, since the most important activities of companies will be increasingly linked to the storage and transmission of information, making the protection of these activities key. Systems must be strongly protected against any cyber-attack due to the need for industries to introduce open-source systems to adapt to the digital transformation of their processes.

Currently, the vast majority of companies do not have the latest technology equipment and infrastructure so they will require greater investment to achieve the digital transformation. Factories will need to gain interoperability capabilities and massively collect data from their production processes to achieve improvements in manufacturing efficiency and flexibility.

Manufacturing and AEC industry companies should start by optimizing their processes or adapting their infrastructures and production. Additionally, many workers will have to adapt professionally, assuming new responsibilities that do not exist today and that will emerge with the paradigm shift. The most important factor on the road to Industry 4.0 is people. If personnel are not aware that this paradigm shift is necessary, the success of its implementation will not be possible.