Do you work with product design and manufacturing processes? How about using one single software collection that offers high-level professional tools for all those workflows?

Product Design & Manufacturing Collection, PDM collection henceforth, is a powerful set of professional software programs with powerful tools fused into computer-aided design, computer-aided manufacturing, and computer-aided engineering (CAD, CAM, and CAE). These products allow you to integrate your product development processes in a way that connects every person involved from concept to production.

If you work within aerospace, automotive, industrial machinery, manufacturing product design, or any other related industries you will know that developing top-performing products has always been a detailed, engineering-intensive, and all-around tough job. With all the different materials and composites available, knowing how each one will work, whilst ensuring your products perform as expected and within warranty, requirements require expert knowledge, endless working hours, and a first-class toolset.

Thankfully, the PDM Collection enables the design and manufacturing industry to shorten the product development lifecycle, cut design and production costs, and boost productivity using these dynamic simulation tools and digital prototyping workflows. This ultimate set of tools allows for designing, testing, management, and manufacturing products with precision.

Create Product Designs

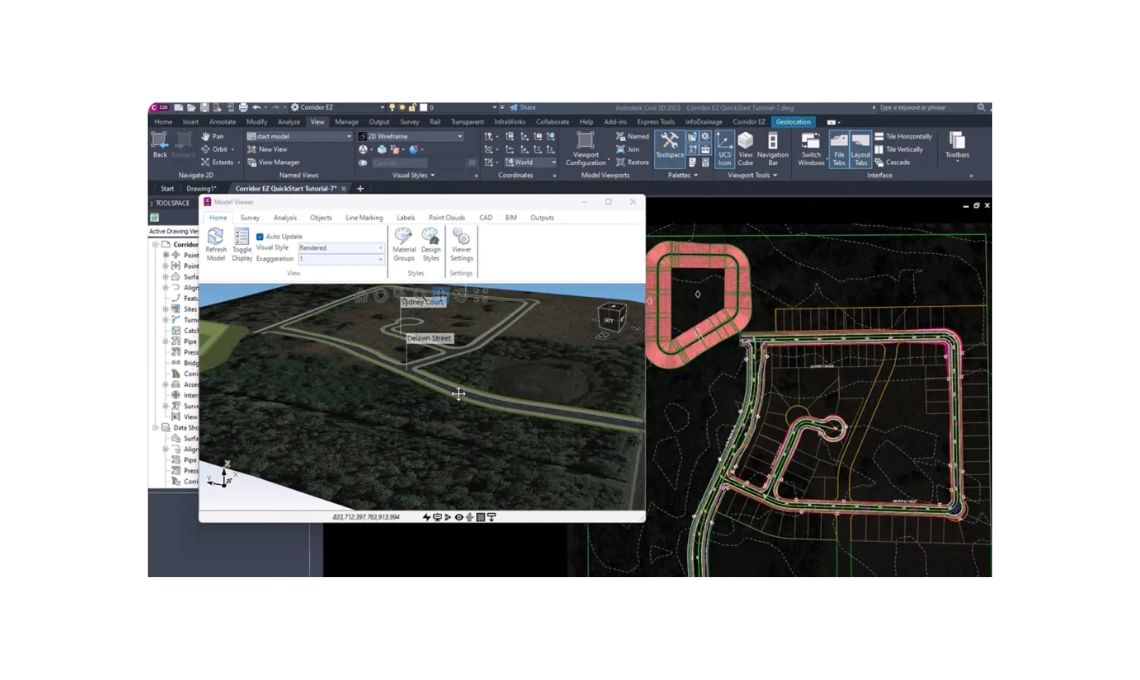

Starting from a single part to massive assembly, you can rapidly create complete product models, and documentation by using professional-grade 3D parametric design capabilities and 2D drafting toolsets. Highly efficient production lines can start from the product design phase thanks to intuitive 2D workflows that can be converted into detailed 3D models for production line layout conceptualization.

The collection allows you to share ideas with impressive visualizations and convey high-fidelity imagery and animation designs that can be generated directly from a 3D model. You can streamline the move to manufacturing and make effective processes that support the transition from design to manufacturing supported by integrated tools that generate multi-axis toolpaths and sheet metal nests.

Explore Design Opportunities

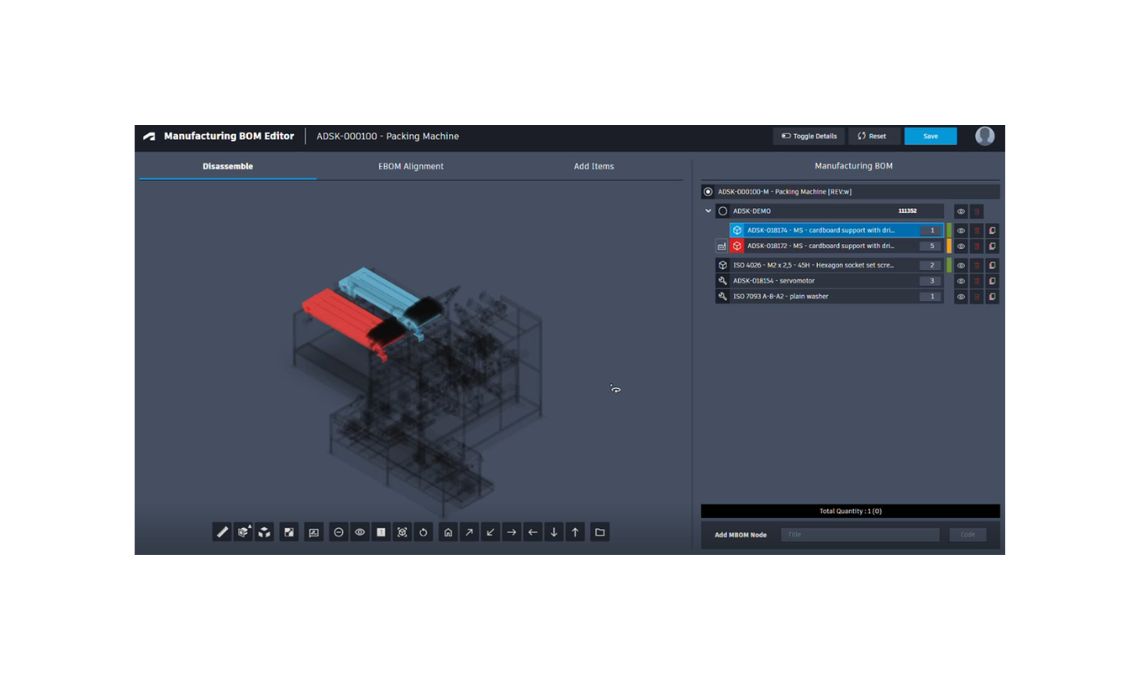

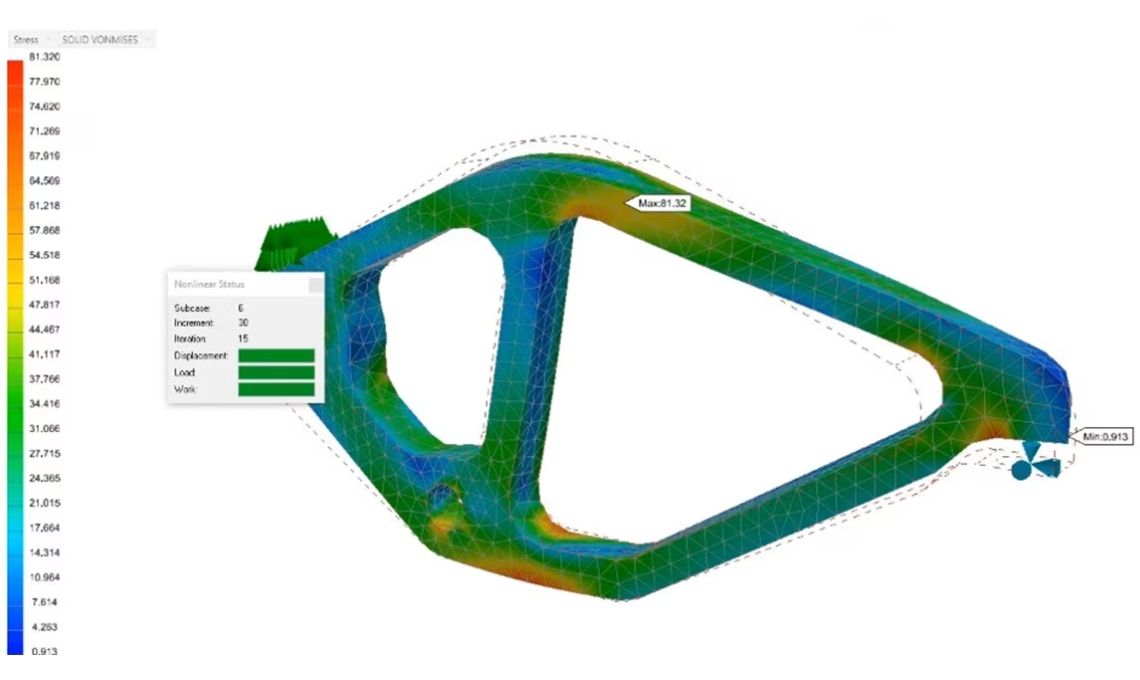

With the PDM Collection, you can explore and expand multiple design possibilities. Generative design capabilities let you make many production-ready design options, review costs and tradeoffs in materials, prevent failures with advanced performance simulation and improve performance and manufacturing processes.

It’s possible to evaluate factory projects before building. Discrete-event simulation capabilities allow you to remove bottlenecks in the process and the installation using proposed production line designs and clash detection between the as-is state. Also, you can evaluate dimensional variation and analyze tighter tolerances based on the cumulative dimensional variation between mating geometry to balance performance and mechanical fit.

Better collaboration and teamwork

PDM Collection allows you to connect everyone with everything. You can combine 2D and 3D CAD capabilities to conceptualize designs, speed up the creation of drawings and documentation, and integrate electromechanical models.

Thanks to the collection, data can be securely shared externally to speed up, simplify and review cycles. You can make it easy to collaborate with your colleagues by controlling your intellectual property in a single location.

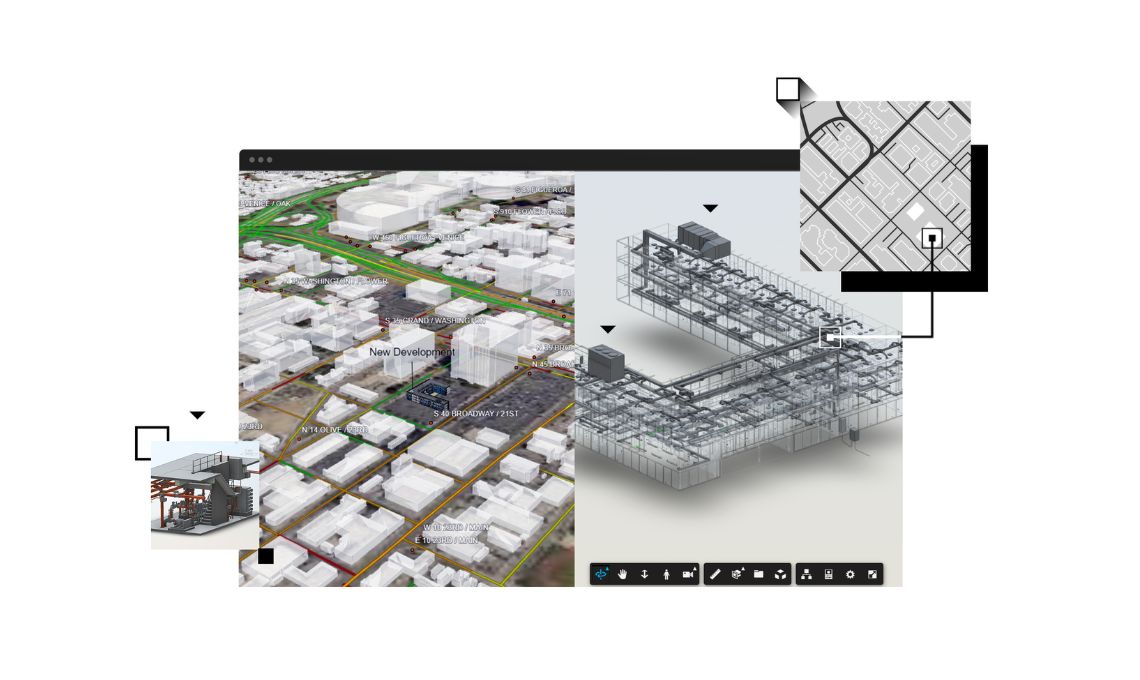

You can reference CAD and BIM models from other software programs that will update whenever a change is made to the original files. In addition, large-scale design projects collaboration can be done effectively by aggregating design data from different sources. Thus, you can unify stakeholders’ communication, check for clashes and simulate installation.

Automate Routine Tasks

Automating routine tasks is a great way for focusing on other project phases. You can use a simple-to-use automation engine to make custom product configurators that capture engineering knowledge and save you time for other project tasks. The collection also allows you to automate templates for assemblies, parts, and drawings for preserving time and reducing errors.

Design validation and manufacturing can be accelerated by automating routine tasks involved in simulation setup in Inventor Nastran. True-shape nesting can also be automated by generating multiple sheet nests for reducing raw material waste and producing comparison reports for reviewing total cost, machining time, and overall efficiency.

Easier license management

While acquiring this collection your company avoids the headache of managing multiple products licenses. In addition, you can choose a single-user subscription or permit teams to share licenses with multi-user access. Once you get a PDM collection, you ensure software compatibility with all team members by accessing previous versions when you need them and deploying updates whenever you want.

That said, we at MicroCAD consider the PDM collection as the most complete ultimate professional-grade design and manufacturing tool. By containing a multitude of high-performing products, this collection enables your entire team to make informed decisions, improve product performance and ultimately be at the forefront of product development.