In the world of water distribution, accuracy is everything. Hydraulic model calibration ensures your virtual network behaves just like the real one. But let’s be honest, traditional calibration methods can be a headache. They often mean juggling scattered spreadsheets, cleaning messy data, and spending weeks trying to line up field data with model outputs.

That’s where InfoWater Pro and Info360 Insight step in. By linking directly to live SCADA and IoT data, these tools make calibration faster, cleaner, and far less painful, freeing up your team to focus on actual problem-solving rather than tedious data wrangling.

Ditching the guesswork

Every water model starts as an estimate. The job of calibration is to make sure the model matches what’s really happening in pipes, tanks, and pumps. That might mean adjusting demand patterns, fine-tuning pipe roughness, or verifying valve statuses.

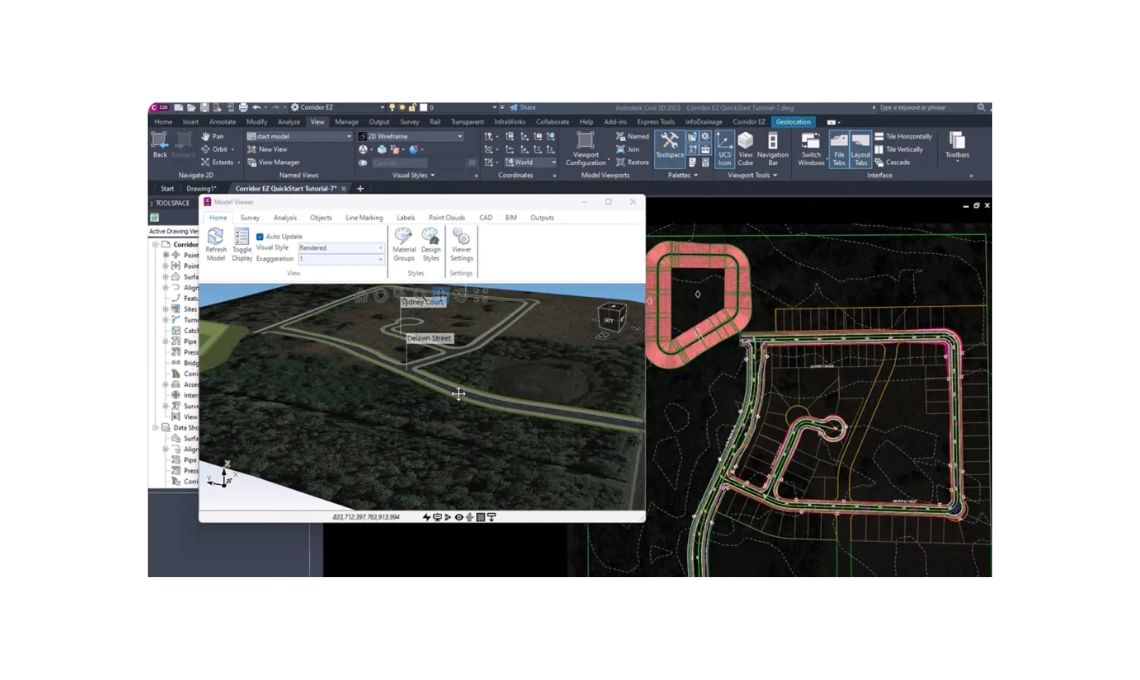

With InfoWater Pro integration, you’re not guessing anymore. Live data flows straight into the model, giving you an up-to-date view of tank levels, pump operations, and pressure readings. This real-time link makes it easier to spot where the model is drifting from reality, and fix it fast.

Cleaning data without losing your mind

SCADA data is gold, but it’s rarely perfect. Gaps in sampling, inconsistent readings, and “dirty” data points can all get in the way of a good calibration. Traditionally, that’s meant hours spent in Excel cleaning things up.

Info360 Insight changes the game by doing the data scrubbing for you. It applies smart rules to filter out bad data, finds patterns in demands, and even keeps tabs on sensor health. Instead of manually fixing errors, you can focus on making sure the model truly represents the real system.

Calibration that keeps up with your system

Your water network doesn’t stand still, and neither should your model. Continuous calibration (where the model is updated daily, weekly, or monthly) means you’re always working with accurate information.

Using InfoWater Pro with Info360 Insight, you can feed in live operational data as often as you like. The system updates boundary conditions, recalculates outputs, and shows you exactly where the model and reality match or don’t. This keeps you ready for operational decisions, not just long-term planning.

Working together, wherever you are

Calibrating a model usually means multiple people are involved: engineers, operators, and consultants. In the old days, that meant trading files, dealing with version mix-ups, and waiting for someone to “send the latest.”

With Info360 Insight’s web-based interface, everyone works from the same, always-updated dashboard. Operators can add real-world observations, consultants can run simulations, and engineers can tweak model settings. All while seeing the same results in real time.

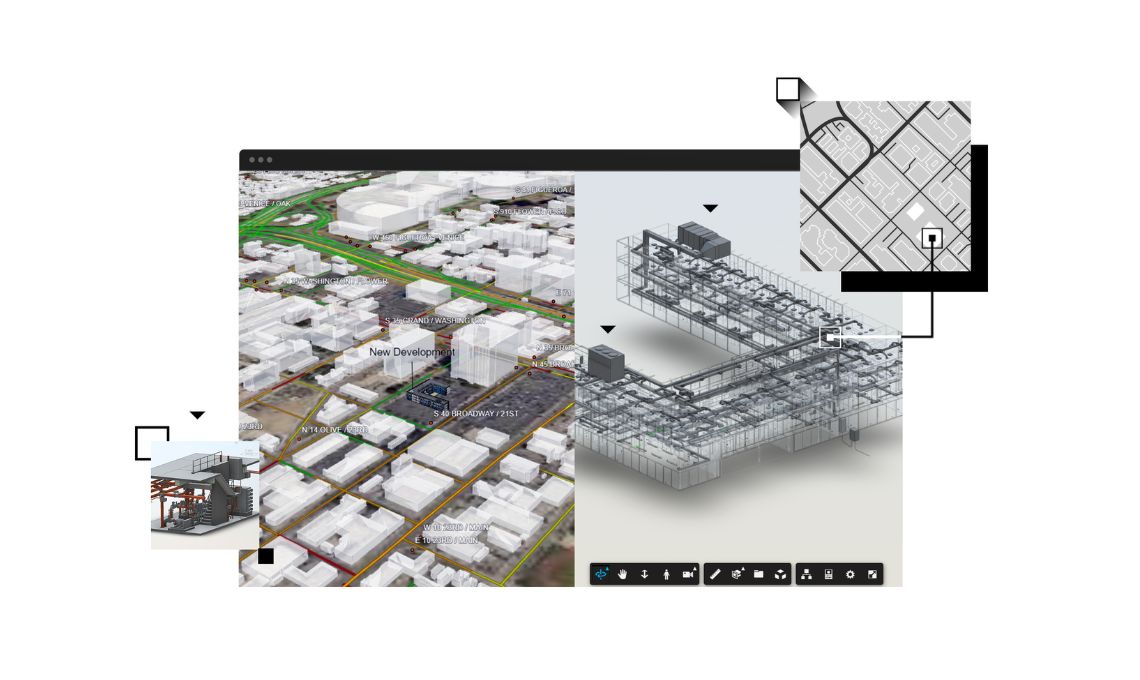

Building a living, breathing digital twin

The ultimate goal of regular, accurate calibration is to create a digital twin, a live model that mirrors your water system in near real time. With InfoWater Pro feeding data into Info360 Insight, you can do far more than just check calibration.

You can detect leaks with the Infrastructure Leakage Index, track non-revenue water at the street level, optimize pumping schedules for lower energy costs, and even spot changes in demand patterns before they cause problems.

Insights that go beyond calibration

Once your model is dialed in, the analytics possibilities open up. Tools like Mass Balance can merge flow data with billing information to highlight exactly where water loss is happening. Demand Management Areas (DMAs) can be created to target maintenance or upgrades in the zones that need them most.

These aren’t just theoretical benefits, they’re practical ways to reduce waste, save money, and improve service reliability.

Faster results, fewer headaches

What used to take weeks can now be done in days or even hours. By removing manual data cleaning, automating updates, and making collaboration effortless, the InfoWater Pro–Info360 Insight workflow helps utilities cut calibration time by up to 40%.

That’s time you can spend analyzing results, planning improvements, and building a water system that’s ready for whatever comes next.

The takeaway

Hydraulic model calibration doesn’t have to be slow or painful. With InfoWater Pro and Info360 Insight, you get a smart, connected workflow that:

- Cleans and processes data automatically

- Updates the model continuously with live information

- Enables easy, real-time collaboration

- Lays the groundwork for a reliable digital twin

The result? A model that’s always accurate, ready for operational decisions, and built to keep up with the real world.