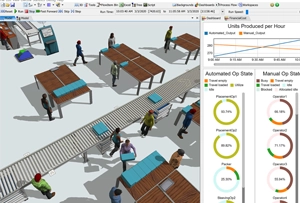

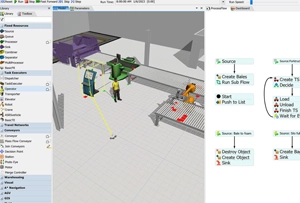

FlexSim: 3D event simulation software

Why use FlexSim?

Accurate predictions and optimizations

A data-driven, evidence-based method to predict how changes will impact production

Minimize risks and disruption

Test “what if” scenarios in a digital model without disrupting real-world operations

Complete, collaborative digital representation

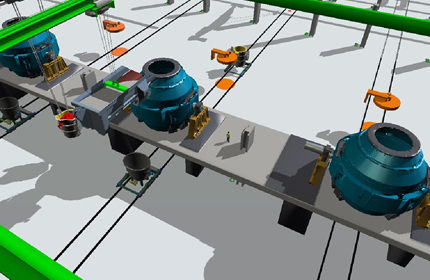

Realistic 3D visuals and process steps to share the factory story with stakeholders

What is FlexSim used for?

FlexSim is used to model production, logistics, and people movement processes, and use that model to visualize, analyze, and optimize the system. FlexSim users could be designing a new factory layout, or they could be responding to a bottleneck on the production floor, or they could be validating a reconfiguration plan to predict its impact on future operations.

Who uses FlexSim?

FlexSim users are typically focused on process improvement and often work in an industrial engineering or manufacturing engineering role. Anyone who wants to better understand or improve production, logistics, and people movement processes can benefit from FlexSim—including project managers, analysts, quality assurance, operations, health systems engineers, Lean/Six Sigma Black Belts, and more.