Finite Element Analysis (FEA) has become a game-changer in modern engineering. It allows manufacturers to test and fine-tune their designs in a virtual environment before committing to costly prototypes or production runs.

Within the Product Design and Manufacturing Collection, Autodesk Inventor Nastran delivers advanced tools for stress, dynamics, and thermal analysis directly inside Inventor, while Autodesk CFD specializes in simulating fluid flow and heat transfer with the added advantage of cloud solving. Together, these solutions help engineers create safer, more efficient, and high-performing products, while keeping costs under control.

What FEA really means for designers

Think of FEA as a virtual testing ground. Instead of building a product and hoping it will perform as expected, engineers use FEA to see how it would behave in real life under pressure, heat, vibration, or fluid movement.

The magic lies in breaking down the design into thousands (or even millions) of small elements. These elements, connected at points called nodes, create a detailed “mesh” of the product. By applying material properties and physical laws, the software can predict how the whole product will respond under different conditions.

This approach removes a lot of guesswork and makes it easier to design with precision from the start.

From idea to insight: How FEA works in practice

Setting the stage

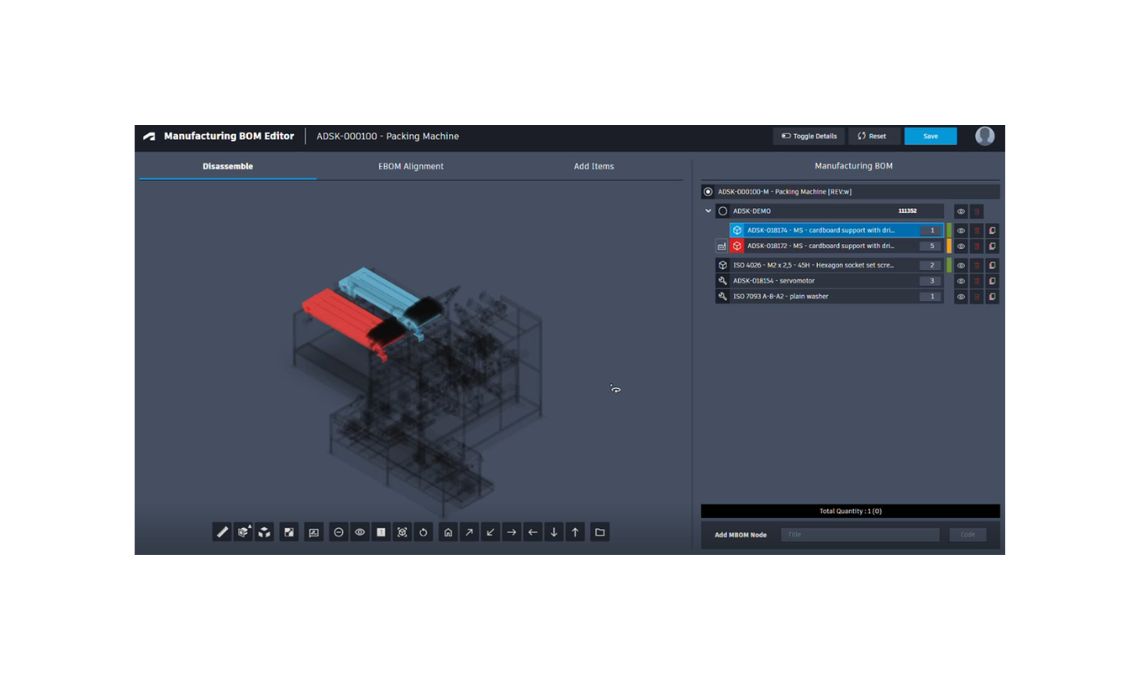

The process begins by defining the product’s shape, materials, and the conditions it will face. Then, the model is split into small elements through meshing, and forces or temperatures are applied to simulate real-world scenarios.

Crunching the numbers

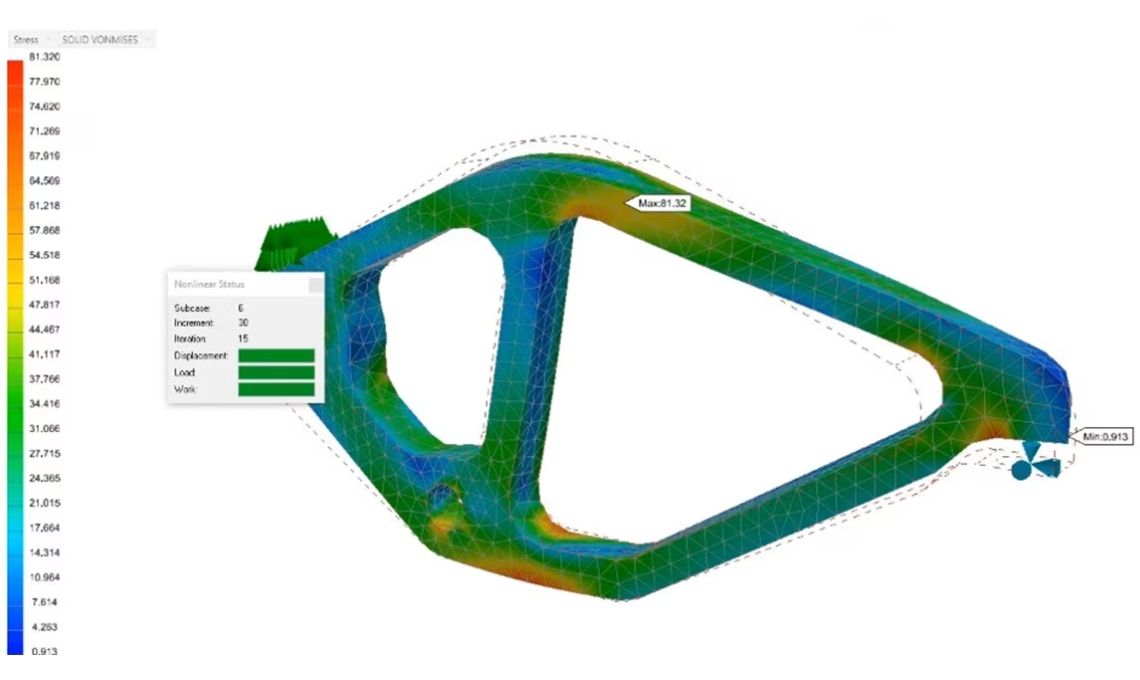

Once the setup is complete, the software runs calculations to determine how each element reacts. The output? Detailed data on things like stress points, deformation, and heat distribution.

Reading the results

Finally, engineers visualize the findings using colorful graphics and animations. This makes it easy to spot potential weak spots or areas where performance could be improved, long before the first prototype is made.

Why manufacturers can’t ignore FEA

Designs that perform from day one

With FEA, you can experiment with different versions of a product without physically building them. That means you can refine your design until it’s both efficient and reliable, before production even begins.

Big savings in time and cost

Finding and fixing problems early means fewer prototypes, fewer redesigns, and less wasted material. The result: faster time-to-market and more room in the budget for innovation.

Products that pass the safety test

FEA simulations let you see how a product will handle stress, heat, or fluid pressure in extreme conditions. This helps ensure it meets industry safety standards and performs consistently in the real world.

Smarter use of materials

By running tests virtually, engineers can choose the right materials and reduce excess use, leading to lighter, stronger, and more sustainable products.

Autodesk solutions that make it happen

Inventor Nastran: Precision inside your CA

Inventor Nastran brings advanced simulation capabilities right into Autodesk Inventor. It handles everything from simple stress checks to complex thermal and dynamic analyses, without leaving your design workspace.

Features like intelligent meshing, guided inputs, and customizable workflows make it easier to get accurate, actionable results quickly.

Autodesk CFD: Mastering fluid flow and heat transfer

Autodesk CFD is built for understanding how fluids and heat move through your designs. Whether you’re optimizing cooling systems, improving ventilation, or reducing drag, CFD simulations give you detailed insights. Plus, cloud solving speeds up the process while keeping your local computer free for other tasks.

Real-World payoff of integrated FEA

When tools like Inventor Nastran and Autodesk CFD are part of the design process from the start, teams can innovate faster and more confidently. An automotive supplier might simulate engine components to withstand heat and vibration. A consumer electronics brand could optimize airflow for cooling compact devices. In both cases, simulation ensures performance, safety, and efficiency before a single unit is manufactured.

Conclusion

FEA is no longer just for specialists, it’s a must-have for any company that wants to design products that are safe, efficient, and ready for the market. With Autodesk’s Inventor Nastran for detailed structural and thermal analysis, and Autodesk CFD for fluid and heat simulations, engineers can push innovation forward without risking costly mistakes.

In short, integrating FEA into your design process means fewer surprises, smarter material use, and products that perform exactly as intended when it matters most.