Do you think your products need more efficient lifecycle management? Have you ever seen the acronyms PLM and PDM? Are you lost because you don’t know if you need one system or the other… or maybe even both?

The variety of software tools to manage information and product data becomes more complex everyday and can mislead when choosing the most convenient systems for your company.

Start by asking yourself a few basic questions:

-

Is your business manufacturing, or just product distribution?

-

Does your company manufacture more than one product?

-

How many departments, teams and databases are part of your process?

-

Is the product design phase significant to you?

Armed with this basic information, you can now answer the specific questions about the differences between Product Lifecycle Management (PLM) and Product Data Management (PDM) environments.

What is the PLM system?

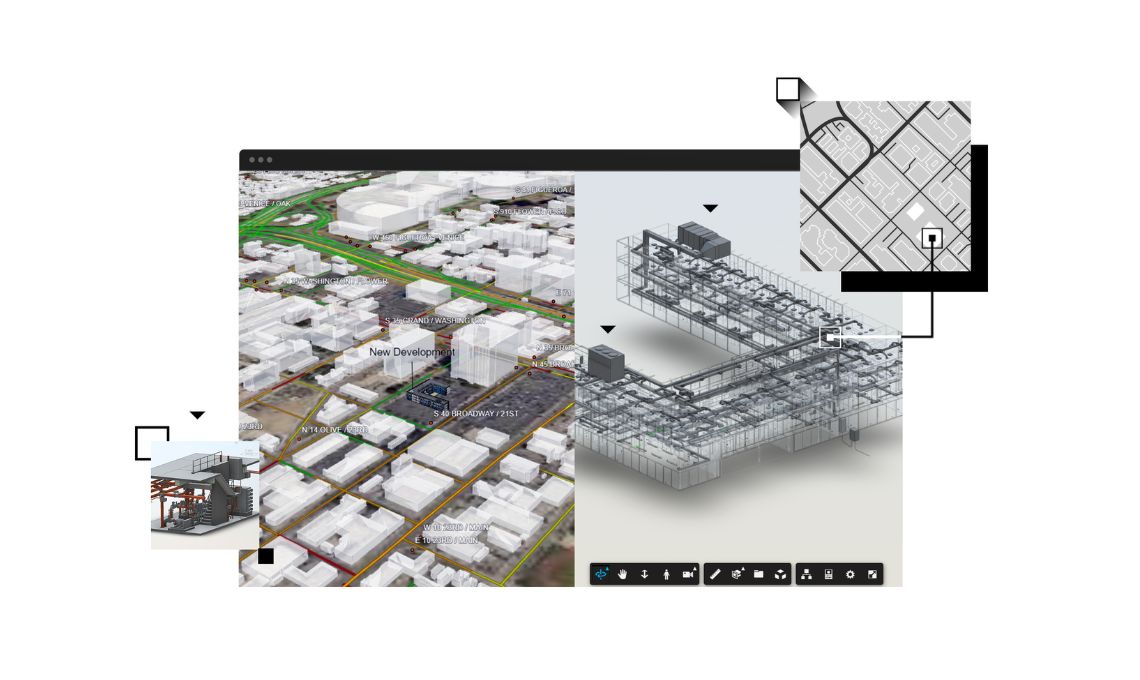

Product Lifecycle Management is a transversal process of follow-up, control and vigilance over the life cycle of a product.

Its operation is strategic and extensive, since it must organize all the related software tools and centralize the databases used in the product development process in a company.

PLM covers the entire life cycle of the product, ensures uniform information and corrects possible errors, from its concept to its manufacture and distribution. It also supervises the correct provision of techniques and data in all intermediate stages, such as quality tests and marketing. In addition, you can identify the obsolescence of products for sale.

To achieve this information, feedback and support are received in this process from other software systems used in the organization of product information, such as the company’s own ERP, a BPM (Business Process Management), a CRM (Customer Relationship Management)… or a PDM.

What is PDM?

Product Data Management (product data management or information management) could be described as a branch of Product Lifecycle Management.

PDM systems capture and manage all product information, ensuring that it is delivered to users in the right context, throughout the product lifecycle.

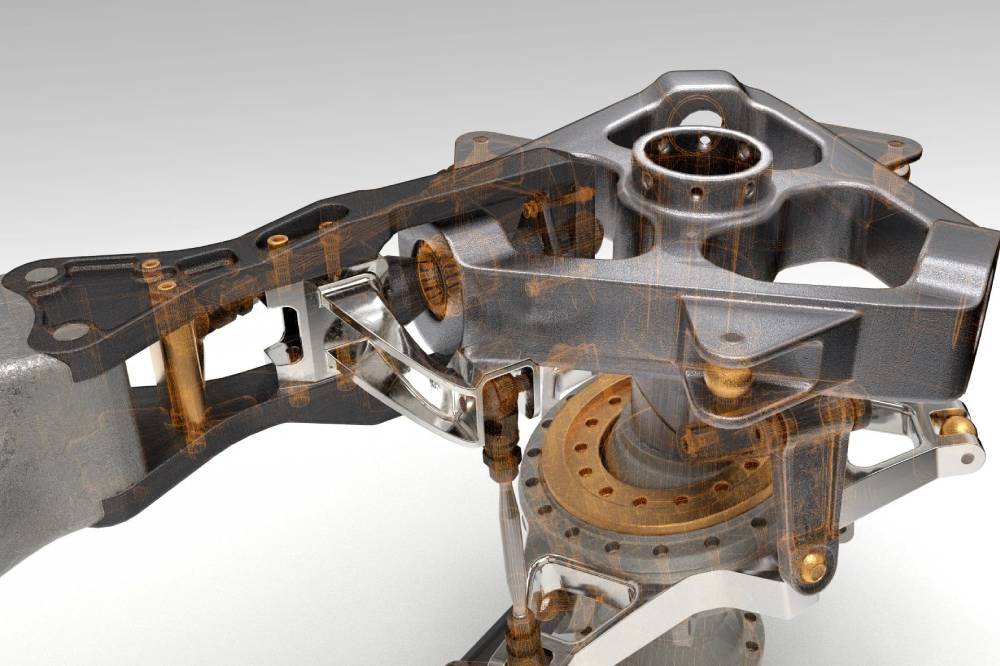

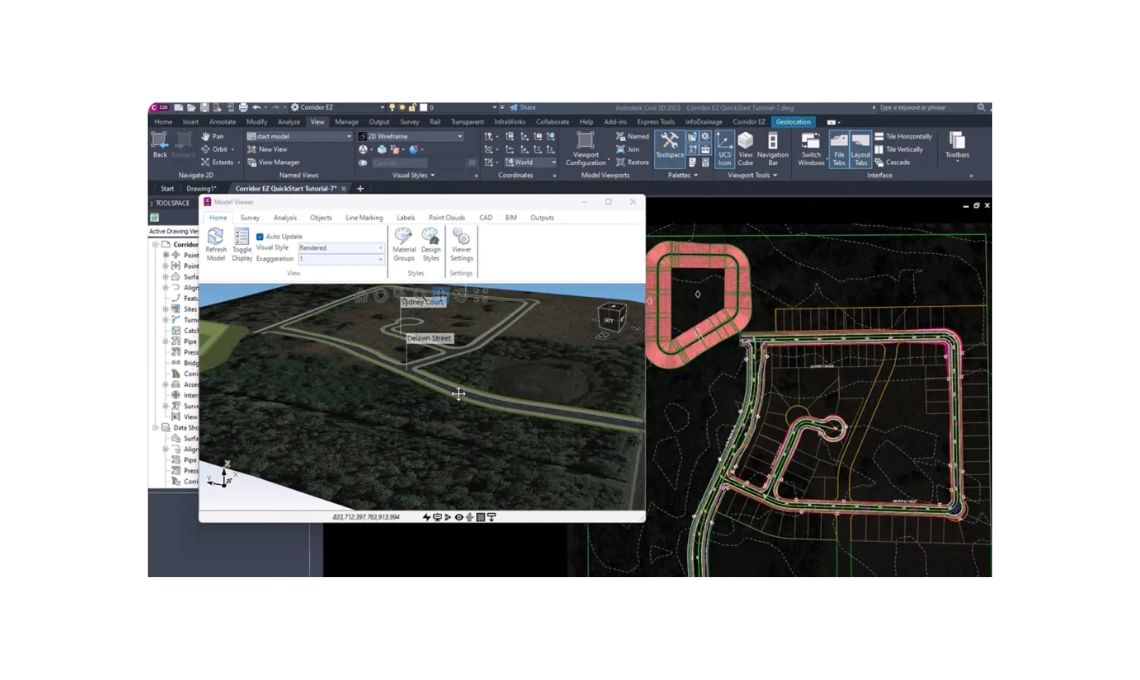

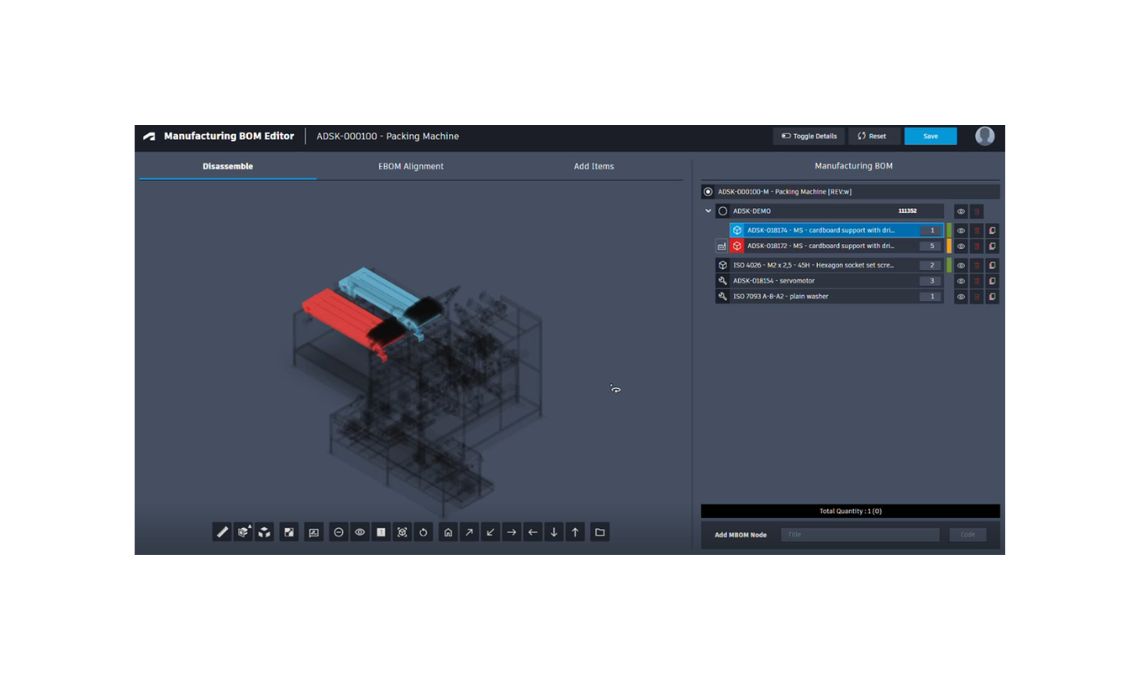

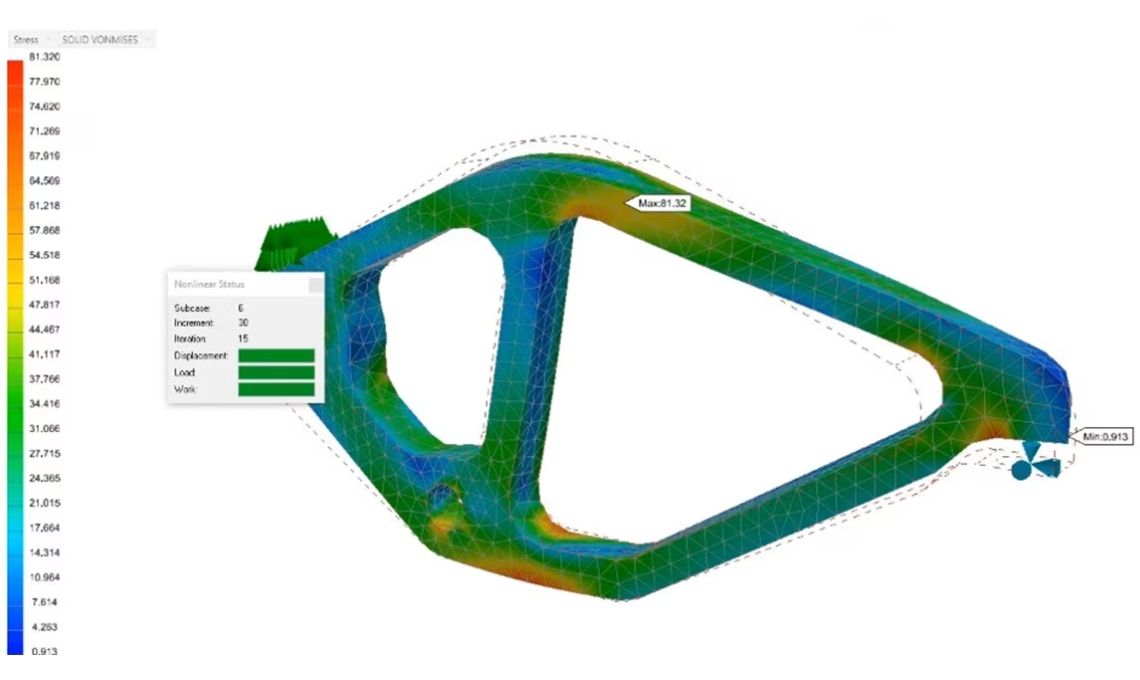

In very particular technical cases, its objective is to manage the metadata and files linked to the design of products developed by a company. It is especially useful for engineers as it stores CAD files or 3D product models and the relationships between them.

The PDM software (such as Autodesk Vault) ensures that the product data is error-free, centralized and easily accessible from all the teams involved in the process (from design to sales), and that the storage system is secure and guarantees the privacy of the company.

In this sense, the PDM process has evolved into a more sophisticated tool, Product Information Manager (PIM), which acts as a centralized and automated data source for products from any sector and size of catalog and company.

PDM vs. PLM: which is better?

There are no categories of best or worst when deciding which environments and software to incorporate into your company.

The criteria must be based on the resources and needs of your company, mainly your volume of resources and equipment involved, and of course your budget.

PDM and PLM processes can be equally useful in the life cycle of a product. In both cases, the PLM and PDM environments can be connected to the company’s ERP to speed up the transmission of data on your network.

1. When to choose a Product Lifecycle Management (PLM) software

The more products a company develops and the more departments, geographies, sources and channels involved, the more convenient it is to hire a PLM system.

But for that it is also necessary to have reached a powerful level and have a good margin of expense, since the costs of implementing and maintaining a PLM are very high.

2. When to choose a Product Data Management (PDM) software

For non-multinational companies with multiple workplaces spread across many countries and complex regulations, Product Data Management software may be more than enough, especially to begin to ensure control over the product design process.

In addition, it will save you resources, as it is easier to install, and initial investment, as it is much more affordable.

Which one do you prefer?

Although some PLM solutions offer CAD file management, they are often not as specialized in this area as PDM software. If the product design stage is very important for your company, definitely opt for PDM, although in the future you will also incorporate PLM.