The Product Design and Manufacturing Collection brings together some of Autodesk’s most powerful tools for engineers, designers, and manufacturers. Among them, Autodesk Fusion and Autodesk Inventor are the stars of the show. Both tools are transforming the way professionals design, test, and produce innovative products.

In the PDM Collection, Fusion and Inventor are setting new standards for design integration, modeling precision, and collaboration. Fusion’s schematic design tools help teams visualize electrical systems using clear symbolic language, while Inventor’s rotation constraints ensure the perfect alignment and movement of parts in complex assemblies. Together, these features simplify workflows, minimize errors, and support a smooth transition from idea to finished product.

What is schematic design and why it matters

Schematic design is a key step in engineering, electronics, and architecture. It’s all about creating visual representations that show how a system works. These diagrams use symbols and lines to illustrate connections, helping teams understand and communicate ideas before physical prototypes are made.

In electronics, schematics show components such as resistors, capacitors, and transistors, along with the paths that connect them. This makes it easier for engineers to design, analyze, and troubleshoot circuits without the need for physical hardware.

In the context of the Product Design and Manufacturing Collection, schematic design helps transform complex ideas into clear, organized plans that guide the entire design process.

Autodesk Fusion: A smarter way to create schematics

Autodesk Fusion is much more than a CAD program. It’s a complete platform that combines schematic design, PCB layout, and 3D visualization in one space. This integration gives designers the ability to move smoothly from concept to production, all while maintaining accuracy and control.

Why schematic design in Autodesk Fusion stands out

- All-in-one environment: Fusion connects schematic design, PCB layouts, and 3D modeling in one platform. When you make a change in one area, it automatically updates across the others, reducing mistakes and saving time.

- Easy to use: Fusion’s drag-and-drop interface and customizable component libraries make it simple to create accurate schematics. Even new users can get started quickly.

- Real-time collaboration: Because it’s cloud-based, teams can work together on the same project, track changes, and share progress easily. Everyone stays updated, no matter where they are.

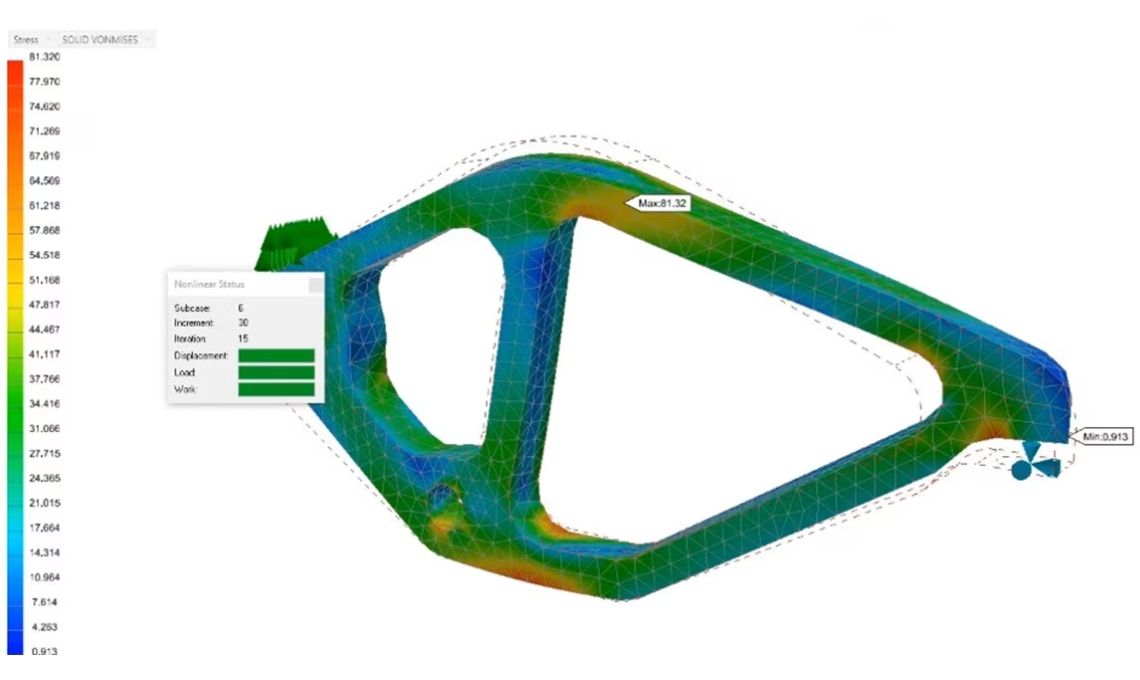

- Built-in simulation: Fusion lets you test your designs before building physical prototypes. You can detect errors early, validate performance, and optimize circuits for better results.

Why Fusion is ideal for modern engineering

Schematic design in Autodesk Fusion plays a crucial role in ensuring smooth collaboration between electrical and mechanical design teams. It helps identify potential errors early, supports design validation, and provides a clear blueprint for product assembly and testing.

By visualizing electrical systems through easy-to-read schematics, Fusion allows engineers to focus on innovation and efficiency. The result is faster development and stronger communication among team members.

Autodesk Inventor: Precision and motion under control

While Fusion focuses on schematic and electronic design, Autodesk Inventor is all about mechanical precision. It’s a go-to tool for 3D modeling and detailed mechanical design within the Product Design and Manufacturing Collection.

One of its most powerful features is rotation constraints, which give designers complete control over how components move and interact in an assembly.

How rotation constraints improve your designs

Rotation constraints in Autodesk Inventor define how parts move relative to one another. This allows designers to simulate realistic motion, maintain alignment, and avoid interference between parts.

For example, if you’re designing a machine with rotating gears or arms, you can use these constraints to ensure that each component moves exactly as it should. This feature reduces the risk of errors, improves reliability, and saves time during the prototyping stage.

Why inventor is essential for complex projects

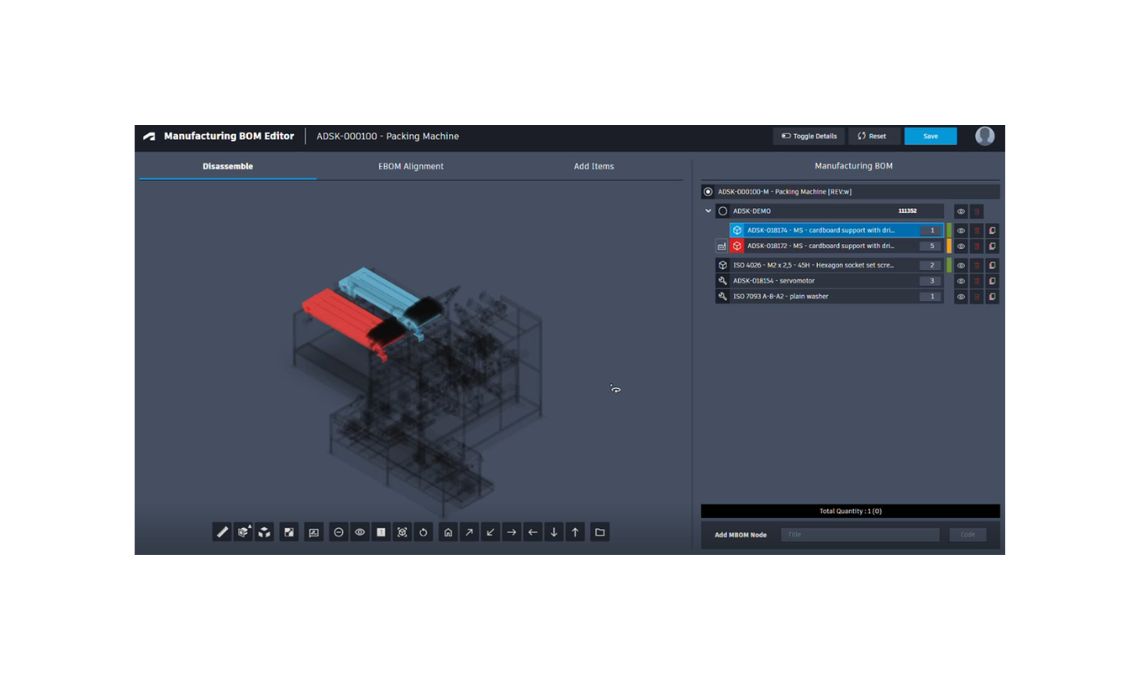

Autodesk Inventor integrates perfectly with the rest of the tools in the Product Design and Manufacturing Collection, including Fusion. Teams can share data between platforms, making it easier to validate both electrical and mechanical aspects of a product.

This level of integration means fewer design errors, faster production cycles, and greater confidence in the final product.

Fusion and Inventor working together

When Autodesk Fusion and Autodesk Inventor are used together, the result is a fully connected design process. Fusion provides intelligent schematic tools for electrical design, while Inventor ensures mechanical precision and stability.

This combination helps teams collaborate more effectively, reduce rework, and bring products to market faster.

The benefits of combining Fusion and Inventor

- Fewer errors: Early visualization of both mechanical and electrical systems prevents design issues before production.

- Better teamwork: Cloud collaboration in Fusion and parametric modeling in Inventor allow engineers to work together seamlessly.

- Faster development: Real-time updates and automated features help teams move from concept to manufacturing quickly.

- Improved product quality: Simulations in both tools ensure that designs perform as expected.

The future of design in the PDM collection

The Product Design and Manufacturing Collection continues to lead innovation in digital engineering. Autodesk Fusion empowers teams with smarter schematic tools and connected workflows, while Autodesk Inventor delivers unmatched accuracy for mechanical design.

Together, they create an ecosystem that bridges every stage of the design process, from electronic schematics to physical modeling and manufacturing.

By combining Fusion’s collaborative design environment with Inventor’s mechanical intelligence, teams can bring ideas to life with confidence, efficiency, and precision. These tools are not just part of the future of product design, they are defining it today.