What really happens to engineering data once it leaves the design team and enters the wider business?

For many organizations, that handoff is where things get complicated. Engineers work carefully inside Autodesk Vault, managing files, revisions, and workflows with precision. Meanwhile, downstream teams in manufacturing, procurement, and operations rely on different systems to track items, bills of materials, and change approvals. When those systems are not connected, information gaps appear.

This is why more companies are looking closely at the value of a connected PDM and PLM environment and, more specifically, why using the Vault connector makes a real difference.

The Role of Autodesk Vault in Product Development

Autodesk Vault is a trusted PDM solution for managing engineering data. It helps design teams control CAD files, manage versions, and follow structured workflows for approvals and releases. Within engineering, Vault brings order and traceability to complex product data.

However, Vault is primarily focused on the design and engineering phase. Once data needs to support broader business processes, such as lifecycle management, sourcing, or change control across departments, limitations start to show. This is not a flaw in Vault, but rather a sign that product development does not stop at engineering.

Where the Disconnect Usually Happens

In many organizations, engineering data must be re-entered or manually transferred into a PLM system or other business tools. Items, BOMs, and change information are often recreated outside Vault. This manual work takes time and introduces risk.

Small inconsistencies can lead to big problems. An outdated BOM can cause purchasing errors. A missed change can impact manufacturing schedules. Over time, teams spend more effort checking data than actually using it. This is where a connector between PDM and PLM becomes less of a nice-to-have and more of a necessity.

Why a Connected PDM and PLM Environment Matters

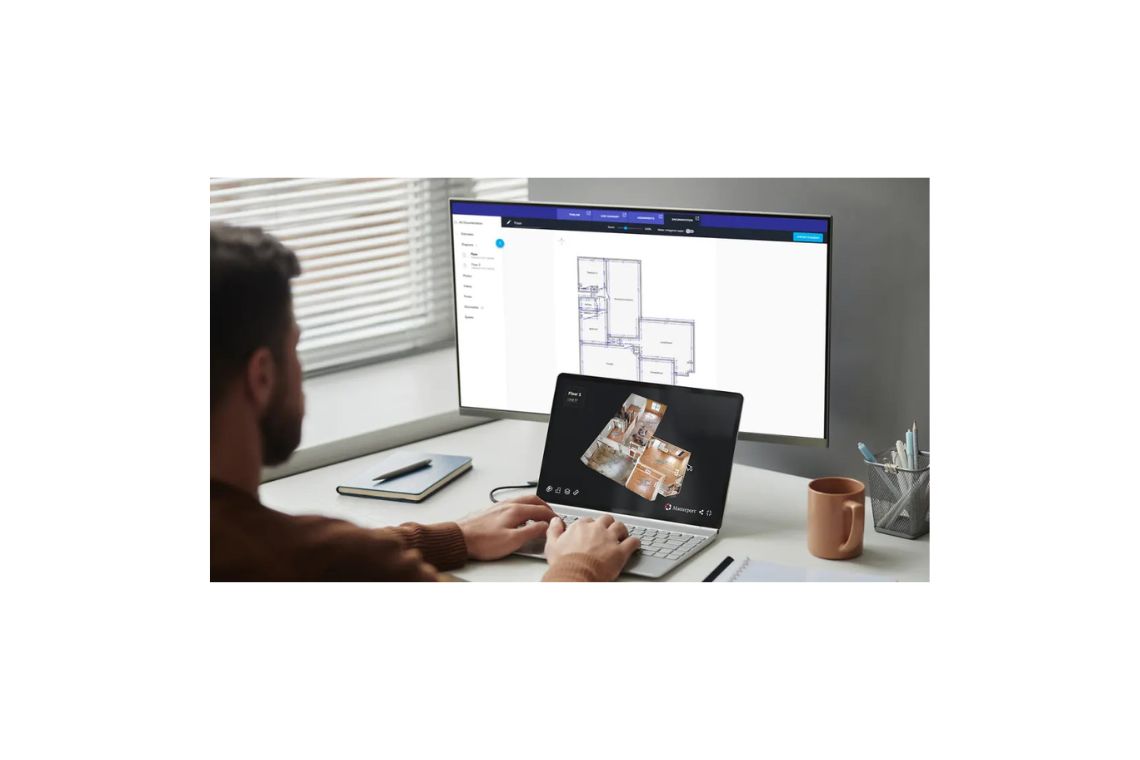

A connected environment ensures that engineering data flows smoothly from design to the rest of the organization. By linking Vault Professional with a PLM system like Fusion Manage, companies create continuity between how products are designed and how they are built, sourced, and maintained.

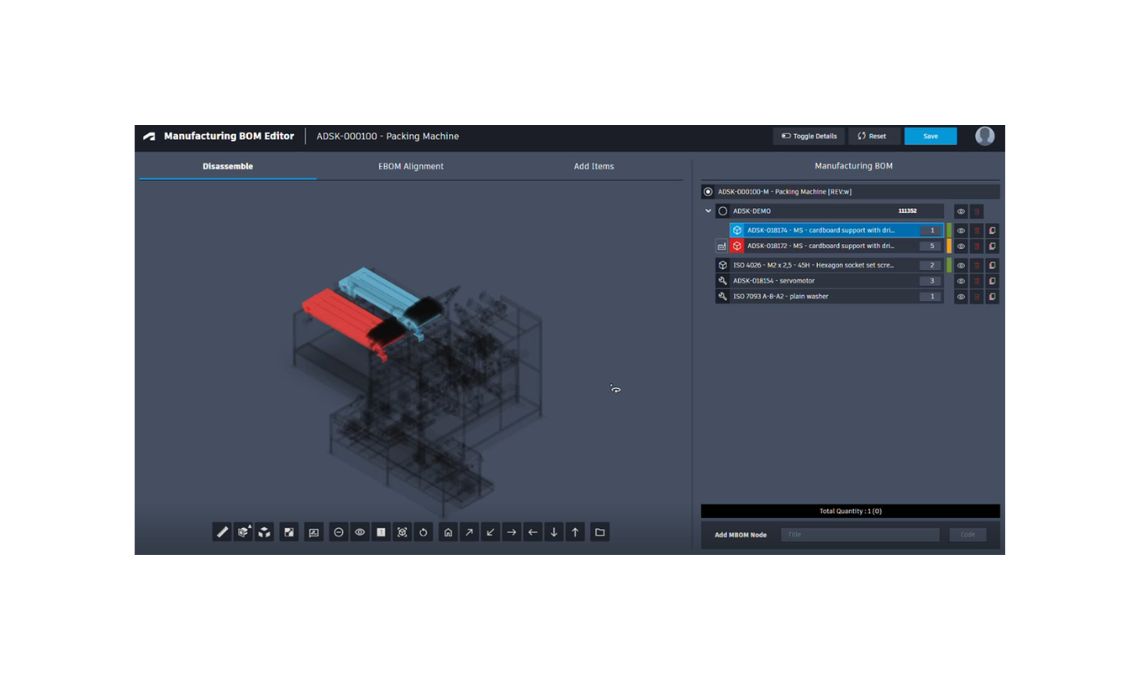

The connector acts as a bridge. Instead of duplicating information, it synchronizes key data such as items, BOMs, and change orders. This keeps engineering and business teams aligned without forcing them to work in the same tool or change their daily workflows.

Reducing Manual Work and Data Errors

One of the most immediate benefits of using the Vault connector is the reduction of manual tasks. When data moves automatically between Vault and PLM, teams no longer need to retype information or export and import spreadsheets.

Less manual work means fewer errors. It also frees up time for higher-value activities, like improving designs or analyzing lifecycle data. Over time, this efficiency adds up, especially for organizations managing complex products with frequent changes.

Better Visibility Across the Product Lifecycle

Vault gives engineers excellent visibility into design data, but PLM systems provide a broader view of the product lifecycle. When the two are connected, that visibility extends beyond engineering.

Stakeholders can see how designs progress into released items, how changes are approved, and how products evolve over time. This shared visibility helps teams make better decisions because everyone is looking at consistent, up-to-date information.

Stronger Change Management Processes

Change management is often one of the most challenging aspects of product development. Engineering changes affect many departments, and delays or miscommunication can be costly.

With a connected PDM and PLM environment, changes initiated in Vault can be reflected in PLM workflows. This ensures that approvals, notifications, and downstream impacts are handled in a coordinated way. Changes become easier to track, understand, and implement across the organization.

Supporting Collaboration Beyond Engineering

Engineering does not work in isolation. Manufacturing, quality, procurement, and service teams all rely on accurate product data. The Vault connector helps extend the value of engineering work to these teams without overwhelming them with design-level complexity.

Each group can access the information they need, in the context that makes sense for their role. This improves collaboration and reduces the back-and-forth that often slows projects down.

A Practical Step Toward Digital Continuity

For Autodesk Vault users, adopting a connected PDM and PLM environment is a practical step toward digital continuity. It does not require abandoning existing tools or redefining every process. Instead, it builds on what teams already do well and connects it to the broader product development ecosystem.

Streamlined Data Synchronization Between Vault Professional and Fusion Manage

By using the Vault connector, organizations can protect the integrity of their engineering data while making it more useful across the business. The result is not just better data management, but smoother collaboration and more confident product delivery.