In manufacturing, efficiency is everything. The more streamlined your process, the more money you save – and the more profit you earn. That’s why Autodesk Fusion (previously Fusion 360) is becoming a game-changer for businesses. It helps manufacturers of all sizes cut waste, improve operations, and boost productivity, all while staying focused on what matters most: delivering value to the customer.

In this article, we’ll break down the basics of lean manufacturing, the types of waste it helps eliminate, and how Fusion Operations supports lean strategies with real-time insights and smarter workflows.

What Is lean manufacturing?

Lean manufacturing is a production approach focused on eliminating waste without sacrificing output or quality. Waste can be anything that doesn’t directly add value from the customer’s point of view. That could mean unnecessary steps in the process, excess materials, or even too much time between tasks.

The goal is simple. Identify what’s valuable, remove everything that isn’t, and constantly look for ways to improve. With tools like Autodesk Fusion, this process becomes more manageable and much more effective.

The five key principles of lean manufacturing

Lean manufacturing follows five key principles that guide businesses toward smarter, more efficient operations.

1. Define value

The first step is to understand what your customers truly care about. What are they willing to pay for? What do they expect from your product? Once you define that value, you can focus your efforts where they matter most.

2. Map the value stream

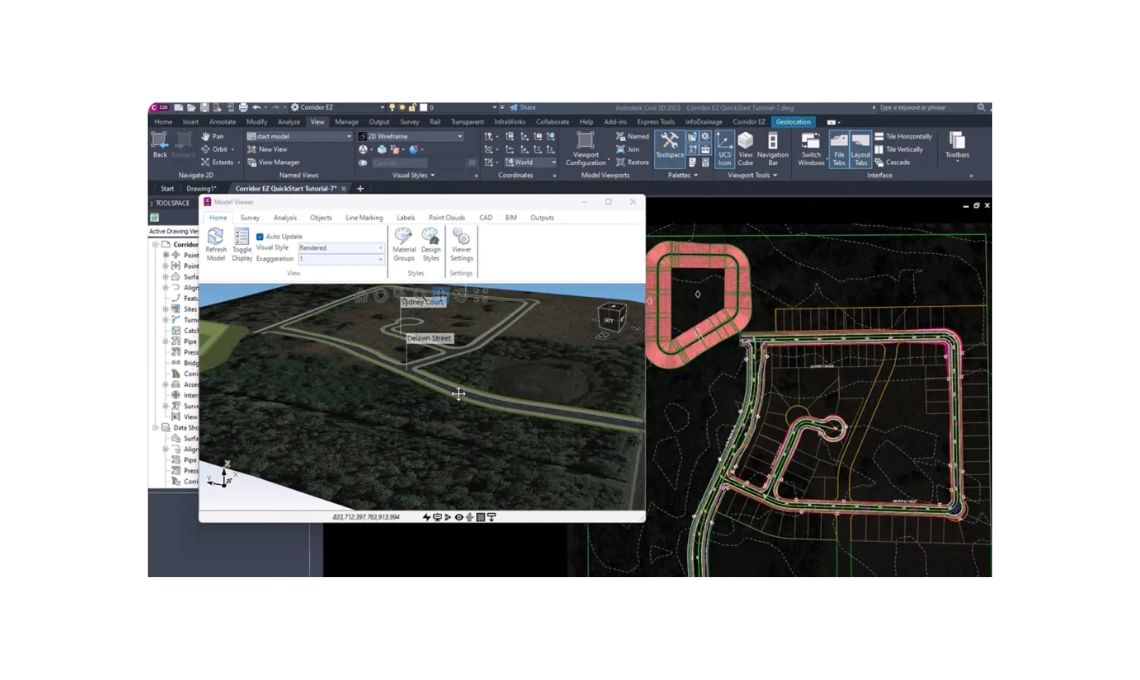

Take a look at every step in your production process. Identify how materials and information flow, then spot the areas where waste is hiding. With Fusion Operations, you can map this out in real time, making it easier to find and fix inefficiencies.

3. Create flow

A smooth, uninterrupted production flow helps keep everything on track. Delays, downtime, or bottlenecks can slow things down and cost money. Fusion provides planning and scheduling tools that help maintain steady progress throughout the entire process.

4. Establish a pull system

Instead of producing based on forecasts, a pull system focuses on real customer demand. You only make what is needed, when it’s needed. Fusion’s demand forecasting and inventory tools support this approach, helping you stay responsive and avoid overproduction.

5. Pursue continuous improvement

Lean manufacturing is not a one-time project. It’s a mindset. Always look for ways to improve processes, reduce lead times, and eliminate unnecessary steps. Fusion offers real-time data and performance tracking, giving your team the insights needed to make smarter decisions.

The Seven Types of Waste in Lean Manufacturing

Lean manufacturing is also about learning to identify different types of waste. Here are the seven most common ones, and how Autodesk Fusion helps eliminate them.

1. Transportation: Unnecessary movement of materials or products adds time and cost without increasing value. Fusion helps optimize layouts and logistics to minimize this type of waste.

2. Inventory: Holding more inventory than necessary ties up cash and takes up space. Fusion Operations lets you manage inventory levels based on actual demand, helping you avoid overstocking.

3. Waiting: Any idle time in the process -waiting for machines, materials, or approvals -is wasted time. Fusion’s scheduling and workflow tools help reduce these delays and keep production moving.

4. Overproduction: Making more than what’s needed leads to extra inventory, wasted resources, and higher costs. Fusion helps align production with actual customer demand so you only produce what will be used.

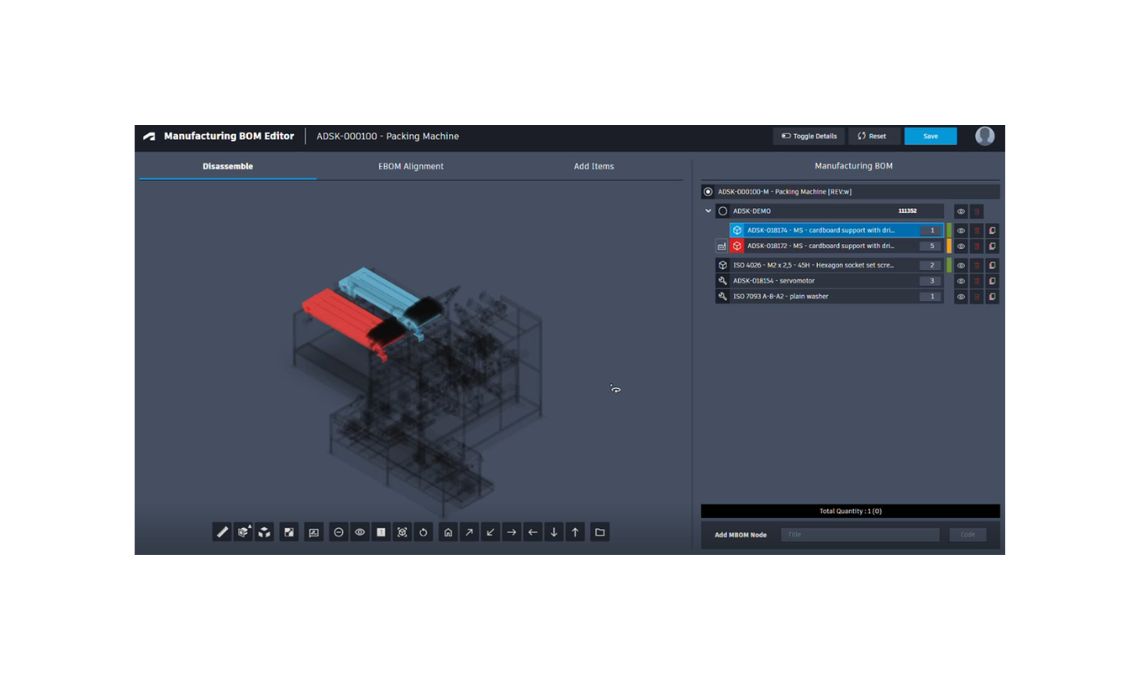

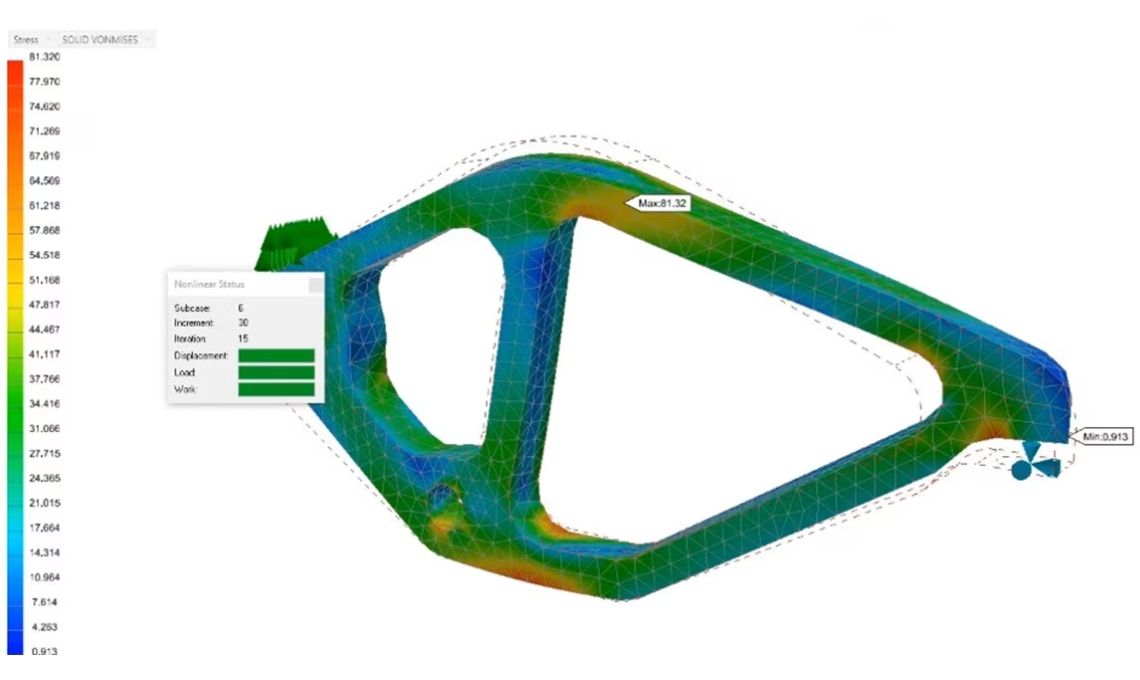

5. Defects: Mistakes require rework or scrap, which costs time and money. Fusion includes quality control features to help detect issues early and ensure higher product quality.

6. Overprocessing: Doing more than necessary, like adding extra features or steps that customers don’t need, adds cost without increasing value. Fusion allows for streamlined planning so teams stay focused on essential tasks.

7. Motion: Excessive movement by workers or equipment can lead to inefficiencies and even injuries. Fusion helps design efficient workspaces by analyzing movement and workflow patterns.

How Autodesk Fusion supports lean manufacturing

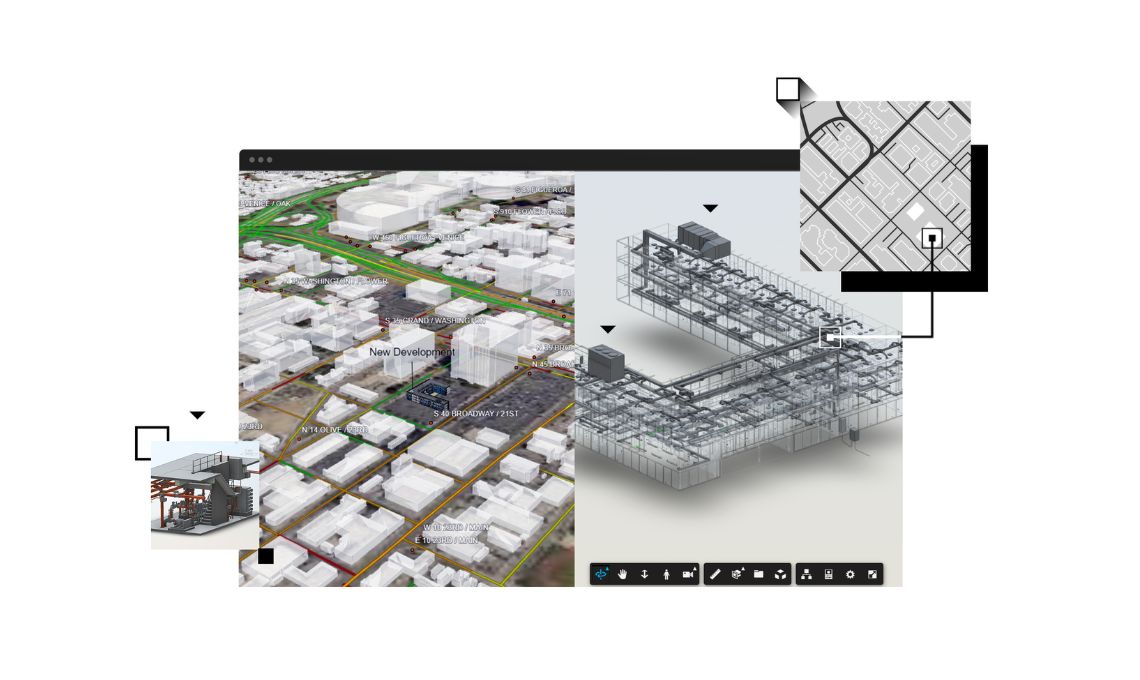

Autodesk Fusion makes it easier to apply lean principles across your operations with smart, connected tools.

- Real-time dashboards let you track key performance indicators across departments

- Smart scheduling helps prevent delays and reduce waiting time

- Cloud-based collaboration keeps teams aligned and informed

- Demand forecasting tools support pull-based production

- Scalable features fit small businesses and large manufacturers alike

With Fusion, you don’t just manage production, you optimize it for long-term success.

Final thoughts

Lean manufacturing is all about working smarter. By focusing on value, eliminating waste, and constantly improving, your business becomes more efficient, more flexible, and more profitable.

When you combine lean strategies with the advanced capabilities of Autodesk Fusion, you set yourself up for a more agile and competitive future. Whether you’re just starting your lean journey or looking to take it further, Fusion is the tool that can help you get there.

Ready to reduce waste and increase profits? It’s time to make the switch to lean manufacturing with Fusion.