Managing a Bill of Materials might seem straightforward, yet it often becomes one of the most complex parts of product development. Keeping data consistent between design and manufacturing systems can quickly turn into a challenge.

CoolOrange provides a set of powerful tools that connect Autodesk Vault and Fusion Manage PLM, enabling teams to streamline BOM control, minimize errors, and maintain full alignment throughout the entire production process.

The Challenge of BOM Complexity

Managing a BOM isn’t just about listing parts. It’s about maintaining a living document that evolves through design, manufacturing, and service. Every product revision, supplier update, or engineering change can ripple through multiple systems, creating discrepancies that lead to confusion, rework, or even production delays.

Without proper synchronization, design teams might be working with outdated versions of assemblies, while purchasing and manufacturing departments rely on conflicting data. The result? Miscommunication, duplicated work, and unnecessary costs… all symptoms of disconnected systems.

That’s where a solution that ties everything together becomes essential.

How CoolOrange Bridges Design and Manufacturing

CoolOrange takes a very pragmatic approach to solving these integration issues. Instead of forcing users to change their existing workflows, it enhances Autodesk Fusion Manage PLM and Vault with tools that connect and streamline processes between engineering and enterprise systems.

At the heart of this approach are powerPLM and powerGate, two modules designed to unify the flow of information. powerPLM connects Vault and Fusion Manage, enabling automatic synchronization of BOM data, item properties, and lifecycle states. This means that when engineers modify a design in Vault, those updates can be reflected in Fusion Manage without manual intervention.

PowerGate, on the other hand, connects the PLM environment to ERP systems, allowing BOMs and item data to flow directly into procurement and production planning tools. This creates a closed loop between design, manufacturing, and supply chain management, one of the key goals of modern product lifecycle management.

Turning EBOMs into MBOMs and SBOMs

One of the standout features of CoolOrange’s integration is its ability to transform different types of BOMs with minimal effort. In most organizations, engineers work with Engineering BOMs (EBOMs), which are optimized for design structure. Manufacturing, however, relies on Manufacturing BOMs (MBOMs), which are organized for production, and service teams use Service BOMs (SBOMs) to manage spare parts and maintenance.

Translating data between these versions has traditionally been a manual and error-prone task. CoolOrange eliminates much of this friction by enabling structured workflows that automatically convert EBOMs into MBOMs and SBOMs while maintaining traceability between them.

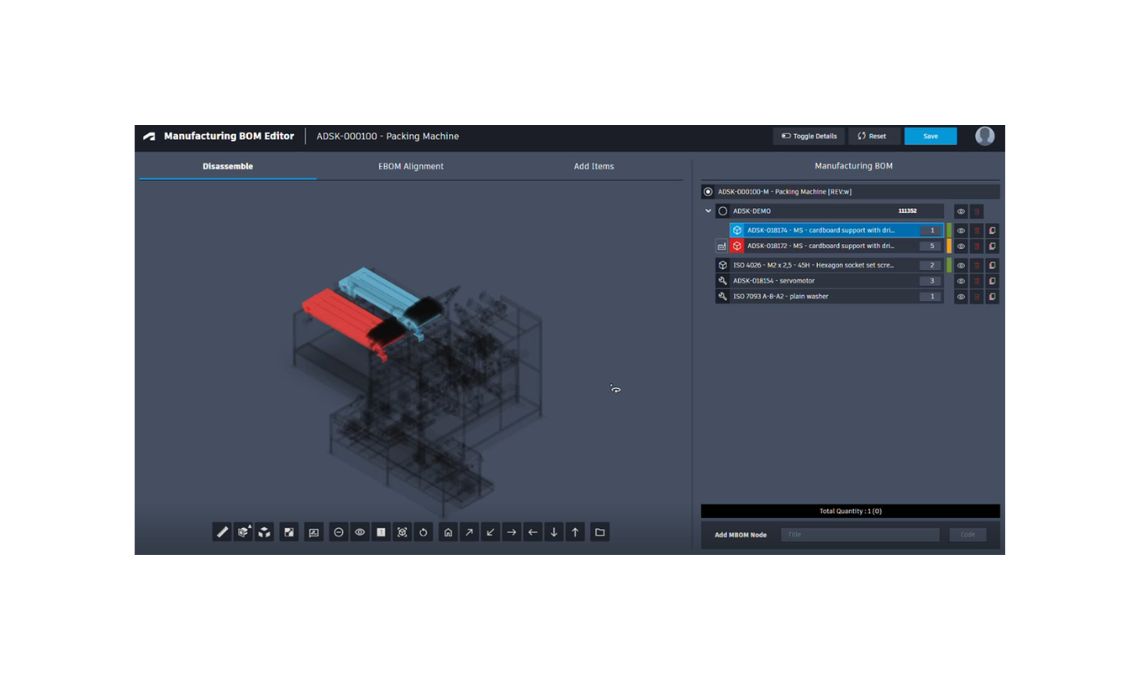

For example, engineers can visually edit a BOM within Fusion Manage, drag and drop components, or add manufacturing-specific items without losing the link to the original design. The built-in validation tools help ensure that every change follows predefined rules, keeping data accurate and compliant with company standards.

Optimized Workflows and Real-Time Collaboration

Another advantage of CoolOrange’s solution is the focus on usability. The BOM Editor, for instance, isn’t just another spreadsheet-style tool. It offers intuitive visual controls that make editing complex assemblies less intimidating.

Teams can create and modify structures directly within Fusion Manage, using features such as inline editing, drag-and-drop organization, and quick access to item details. Changes can be reviewed and approved through automated workflows that ensure the right people are notified at the right time.

This not only reduces the need for back-and-forth emails or meetings but also keeps data consistent across departments. The result is a faster design-to-production cycle, with fewer surprises and more confidence in the integrity of the BOM data.

Connected Data Means Fewer Mistakes

When systems are siloed, the chances of human error increase dramatically. Someone might forget to update a part number, or a supplier change might not make its way into the manufacturing system. CoolOrange’s connected data environment helps prevent these issues by maintaining a single source of truth across Vault, Fusion Manage, and ERP platforms.

This connectivity allows teams to trace every part and every revision, making it easier to comply with regulatory standards, support audits, and manage product recalls if necessary. It also provides visibility across the entire product lifecycle, from design to production and eventually to maintenance and service.

Why Efficient BOM Management Matters More Than Ever

In an era where product complexity is growing and time-to-market is shrinking, efficient BOM management isn’t just an operational advantage, it’s a competitive necessity. Companies that can synchronize their design and manufacturing data seamlessly are better equipped to adapt to change, scale production, and deliver higher-quality products.

CoolOrange’s tools give organizations the flexibility to handle these demands without overhauling their existing systems. By enhancing the native capabilities of Autodesk’s platforms, they create a smooth transition toward more connected, automated, and traceable workflows.

A Smarter Way to Manage BOMs

Ultimately, what CoolOrange offers is a smarter way to manage the information that defines your products. It helps eliminate redundancy, streamline collaboration, and ensure that every stakeholder, from design engineers to production managers, is working with accurate, up-to-date data.

By connecting Autodesk Vault, Fusion Manage, and ERP systems, CoolOrange enables teams to work faster and with greater precision, transforming BOM management from a source of frustration into a driver of efficiency and innovation.