In today’s fast-paced manufacturing environment, precision and adaptability are key to staying competitive. As product designs grow more intricate and timelines shrink, manufacturers are increasingly adopting cutting-edge tools to meet demand.

One standout innovation is 5 axis machining, a method that allows for exceptional control and complexity in CNC milling. With Autodesk Fusion for Manufacturing, this technology becomes even more powerful, integrating advanced CAM capabilities into a seamless cloud-based platform.

From creating complex geometries to minimizing lead times, Autodesk Fusion empowers machinists and engineers with the tools needed to optimize production and innovate faster. Let’s explore how this platform elevates 5 axis machining to a smarter, more efficient level.

Breaking the limits of traditional machining

Conventional CNC machining typically operates along three axes, X, Y, and Z, limiting the cutting tool’s approach to the workpiece. While this setup suffices for many applications, it struggles with intricate parts requiring multiple faces or angles.

5 axis machining introduces two additional rotational axes, allowing the cutting tool to move in five directions simultaneously. This added flexibility lets the tool approach hard-to-reach areas and perform more sophisticated cuts with fewer repositionings. Depending on the job, manufacturers can choose between:

- Positional 5 axis (3+2 machining): The tool rotates to a fixed position before cutting along three axes.

- Simultaneous 5 axis: All five axes move at once to follow complex toolpaths dynamically.

This leap in movement capabilities means greater design freedom and more efficient production especially for industries like aerospace, automotive, and medical devices.

Why more axis mean better outcomes

The transition to 5 axis machining delivers a host of tangible benefits that impact productivity, part quality, and costs. Here’s why manufacturers are embracing this technique:

One setup, many angles

5 axis machining drastically reduces the need to stop and reposition a part. With the tool able to reach multiple sides in one operation, you save time and reduce setup errors two factors that significantly impact production efficiency.

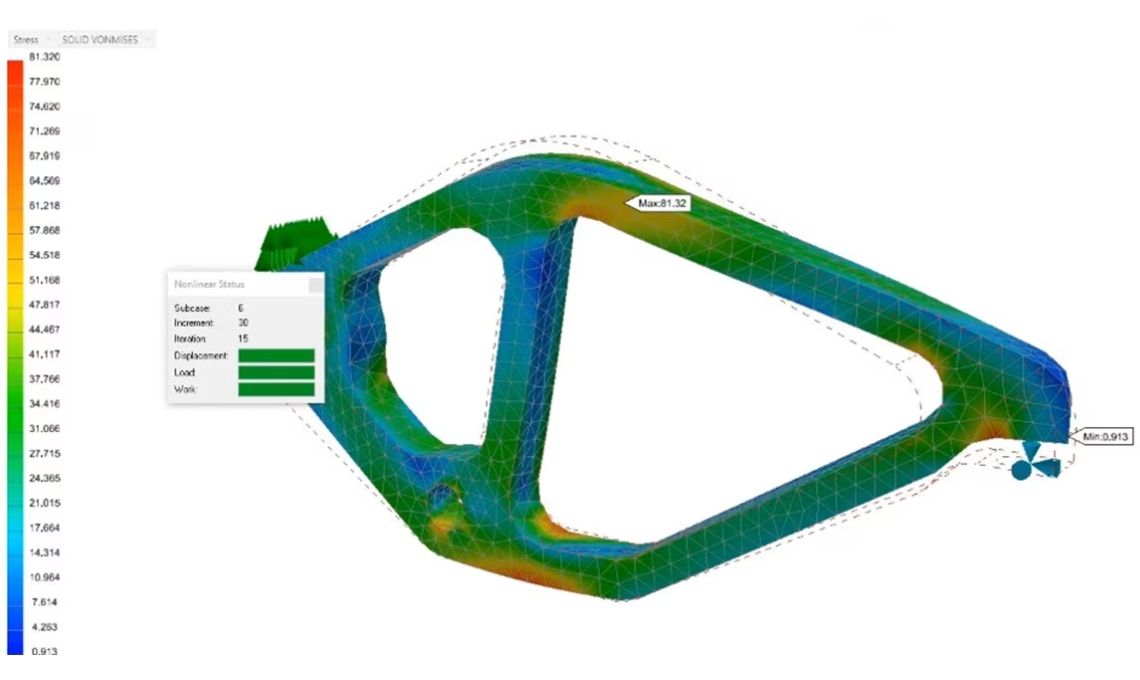

Precision without compromise

Fewer setups mean fewer chances for misalignment or measurement drift. The result? Tighter tolerances and better part consistency. This is especially important for high-performance components that demand exacting standards.

Flawless finishes, faster

By optimizing the tool’s orientation and maintaining consistent cutting conditions, 5 axis machining improves surface finish. Smooth contours, clean edges, and minimal need for hand-finishing make the process ideal for both aesthetics and functionality.

Design without constraints

5 axis machining opens up new design possibilities. Deep cavities, undercuts, compound curves, what once required complex fixtures or multiple machines can now be achieved with one setup and one toolpath.

Shorter cycles, quicker deliveries

With fewer setups, smoother toolpaths, and better surface quality, 5 axis machining accelerates the overall production timeline. For manufacturers competing on speed, this advantage is a game-changer.

Powerful CAM inside Autodesk Fusion

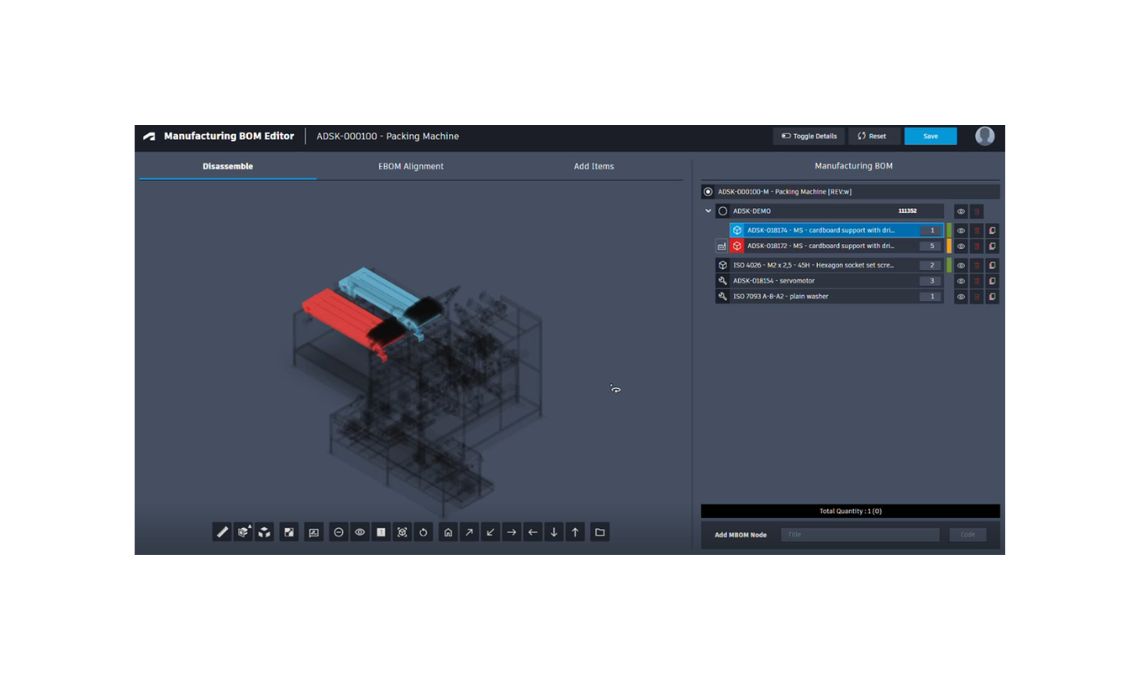

Where many CAM systems require separate software or costly integrations, Autodesk Fusion brings advanced machining tools into a unified platform. As part of its comprehensive Fusion for Manufacturing suite, it offers state-of-the-art features tailored for both positional and simultaneous 5 axis operations.

Full control with adaptive toolpaths

Fusion’s CAM workspace includes intelligent toolpath strategies like adaptive clearing, contouring, and multi-axis finishing. These paths are optimized to maintain ideal tool engagement, reduce air cuts, and extend tool life all while delivering the precision expected from advanced 5 axis machining.

See the cut before it happens

Built-in simulation tools let users preview every movement of the machine before making the first cut. This virtual testing helps detect collisions, tool gouges, and travel limits, providing peace of mind and preventing costly errors.

Smart inspection with in-cycle probing

Fusion also supports in-cycle probing, allowing machines to automatically measure, align, and inspect parts during the machining process. This closed-loop feedback improves accuracy, automates quality checks, and enables dynamic toolpath adjustments all without stopping the machine.

A connected workflow from design to production

One of Autodesk Fusion’s standout advantages is its unified approach to product development. Rather than jumping between different software environments, users can design, simulate, program, and machine all in one platform.

Parametric updates made easy

Design changes? No problem. Fusion maintains a parametric link between the CAD model and the CAM setup. If the model is updated, the toolpaths automatically update too keeping everything in sync and saving valuable programming time.

Collaborate anytime, anywhere

As a cloud-native platform, Autodesk Fusion enables seamless collaboration between teams, suppliers, and clients. Engineers and machinists can access the same up-to-date files from any device, speeding up reviews and approvals.

Lower overhead, higher efficiency

Advanced manufacturing tools don’t have to come with a heavy price tag. Autodesk Fusion’s subscription based pricing makes 5 axis machining more accessible to small and mid-sized businesses. With its integrated design-to-manufacture capabilities, companies eliminate the need for multiple software licenses, saving money while gaining flexibility.

Additionally, reduced rework, less scrap, and faster turnaround times contribute to long-term cost savings and higher profit margins. It’s not just about smarter machining, it’s about smarter business.

Unlocking innovation on the shop floor

By combining powerful CAM features, intelligent automation, and real-time collaboration tools, Autodesk Fusion transforms 5 axis machining from a niche capability into a daily driver for modern manufacturers. Whether you’re creating molds with deep undercuts or aerospace components with complex contours, Fusion delivers the tools to machine confidently, efficiently, and creatively.

The manufacturing landscape is evolving and with Autodesk Fusion for Manufacturing, your workflow evolves with it.